Design Tips to CNC Machining

Low-volume Production for Housing with Vacuum Casting Process

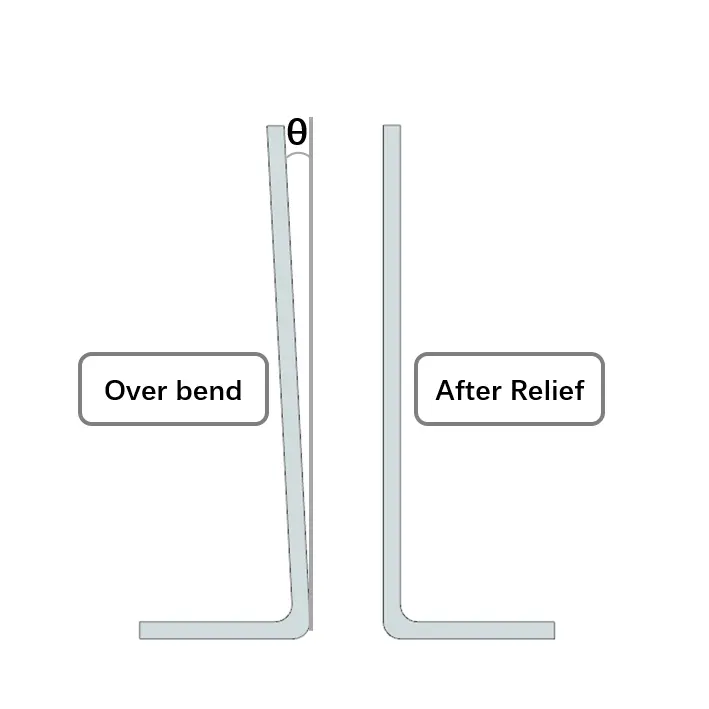

1. Sheet Metal Tips on Bending and Reliefs Design

When you design sheet metal parts, we have many sheet metals tips for you. First, please keep consistent to the bend radius. This little radius is created by punch and die set on a press brake, so design with the standard and consistent bend radius can save much time and cost. Second, try to keep a minimum bend radius to prevent parts from fracturing or distorting. We recommend that the smallest bend radius should be equal or bigger than the sheet thickness. At last, keeping bends in the same plane in one direction does help to save time and cost by preventing part reorientation—especially for sheet metal parts with complex bending. To prevent crack and match +/-1degree bend tolerance, OrideTech will place bend reliefs in strategic part location which is slightly over than nominal.

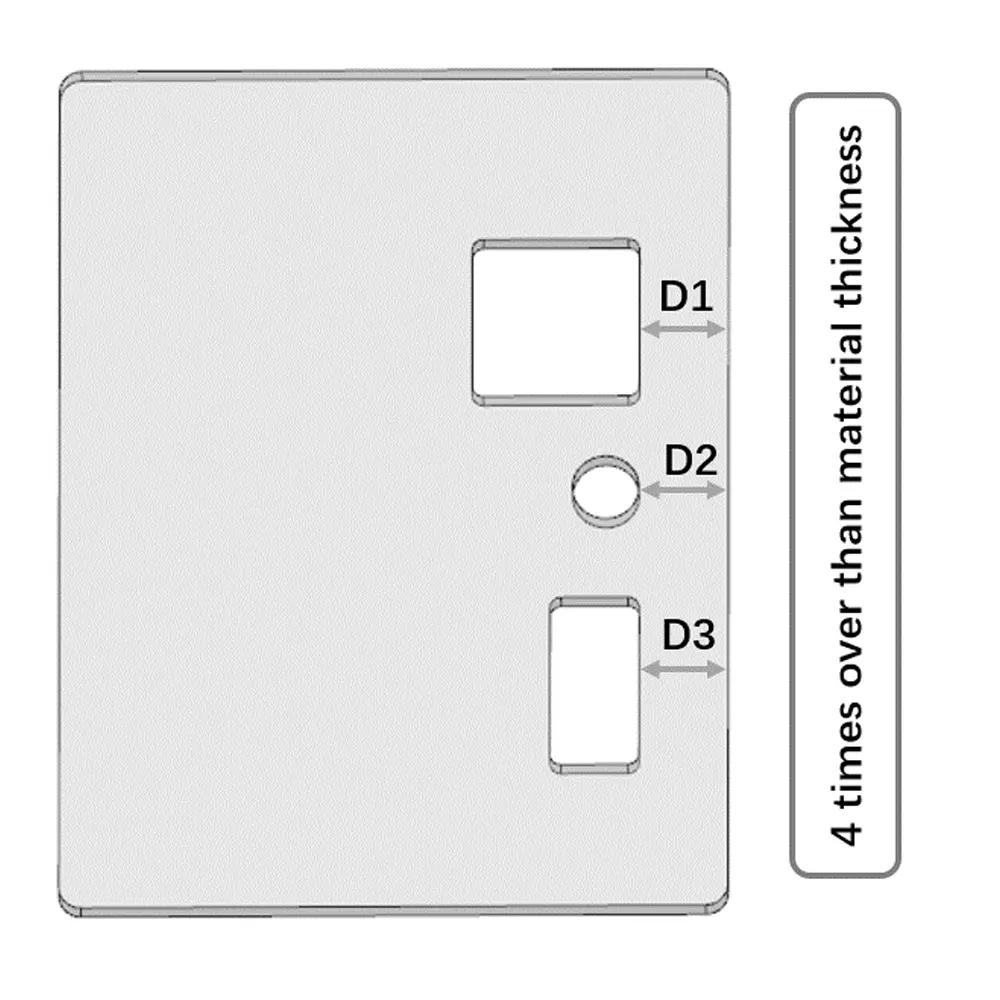

2. Sheet Metal Tips on Holes and Slots Design

During your design, when you place a hole or slot on your sheet metal parts, these sheet metal tips here are helpful for you. First, please keep four times the material thickness or over from the nearest wall, part edge, bend line or other features. Second, try to avoid tiny holes and slots in thick and hard material. The punch strength and life span need to be took into consideration. OrideTech can do holes and slots with tolerance of +/-0.10mm unless otherwise specified. At last, try to avoid designing chamfer or blind slot features since they need extra-machining like CNC machining and this will increase your cost and lead time. All these sheet metal tips are from Oridetech experience and can do helps to save time and money for your project.

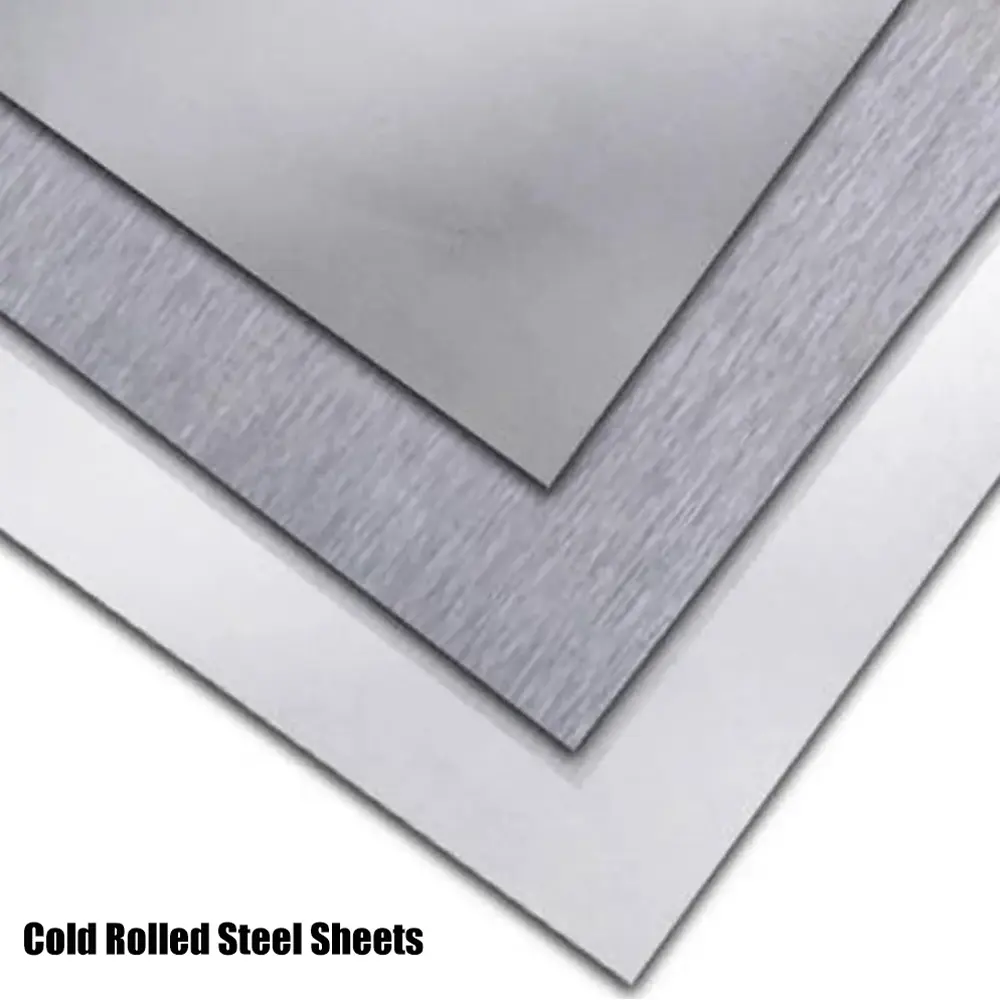

3. Consider Finishing and Welding Costs for Sheet Metal Fabrication

Finishing and welding are something complex to sheet metal design. If welding is required, you have one choice which is using uncoated cold rolled steel. Afterward, you can get your parts coated to enhance anti-corrosion properties. The downside to this is that it will definitely increase your lead times and cost. The sheet metal tip from OrideTech is to retake a look at your designs and see if there are any ways to avoid welding. If you redesign your product without welding, you can use pre-finished steel. OrideTech has resource to do finishing such as anodizing, chromate plating, zinc, stainless steel passivation, and powder coating for your samples. After you finish designing your sheet metal product, remember to check the sheet metal design tips from OrideTech and describe your finishing requirements.

4. Sheet Metal Tips on Accelerating Your Design and Saving Cost

OrideTech, from its experience, provides you sheet metal tips below to accelerate your project and save cost

- Choose sheet metal material with finishing for your designed part.

- Avoid to design complex features for sheet metal fabrication if possible.

- Be flexible with your designs to any processes’ limitation and changes.

- Be strict and careful to choose fasteners for your sheet metal parts.

- Consider to remove printing and laser engraving in prototyping if possible.

- Choose common and easy-get standard material for sheet metal design.

If you want to learn more sheet metal tips, please visit our Facebook page and YouTube Channel.