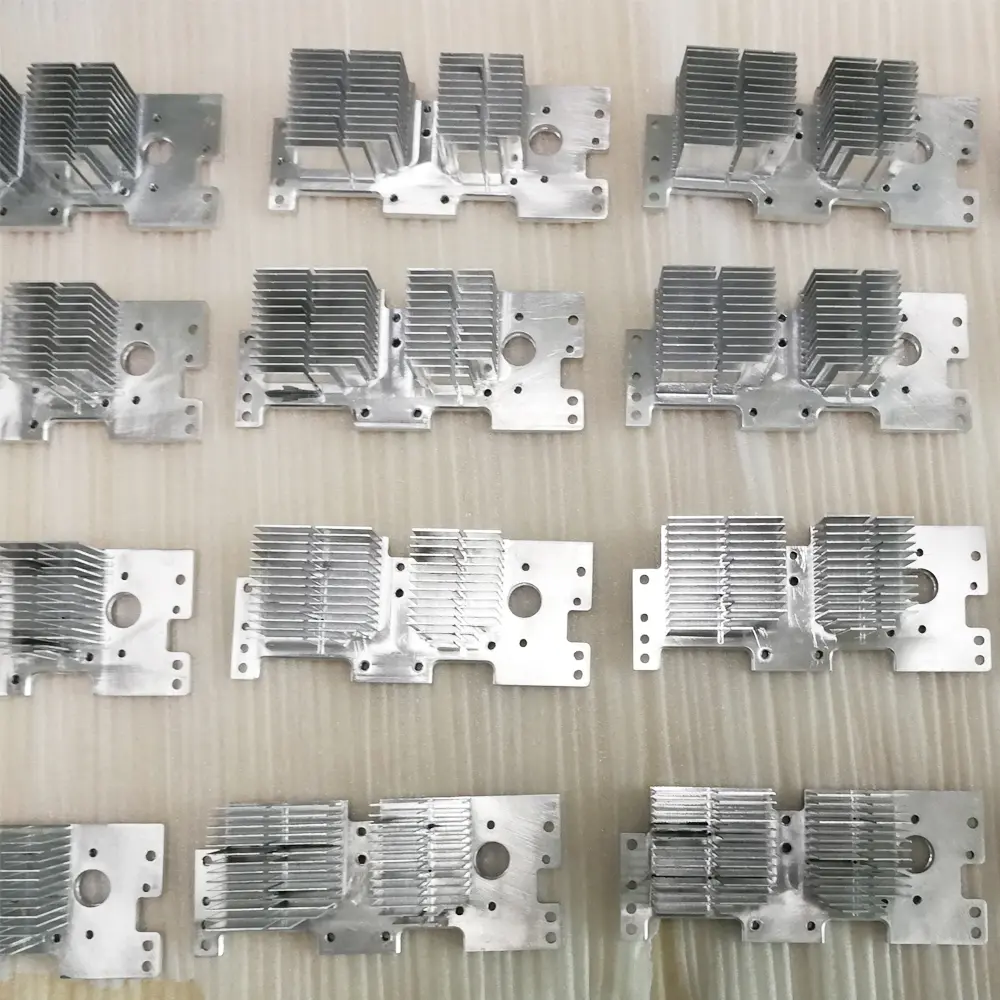

Aluminum VS Copper Heatsink with High & Thin Fins in Which Cutting Depth is Nearly 20 Times Bigger than Cutter Diameter

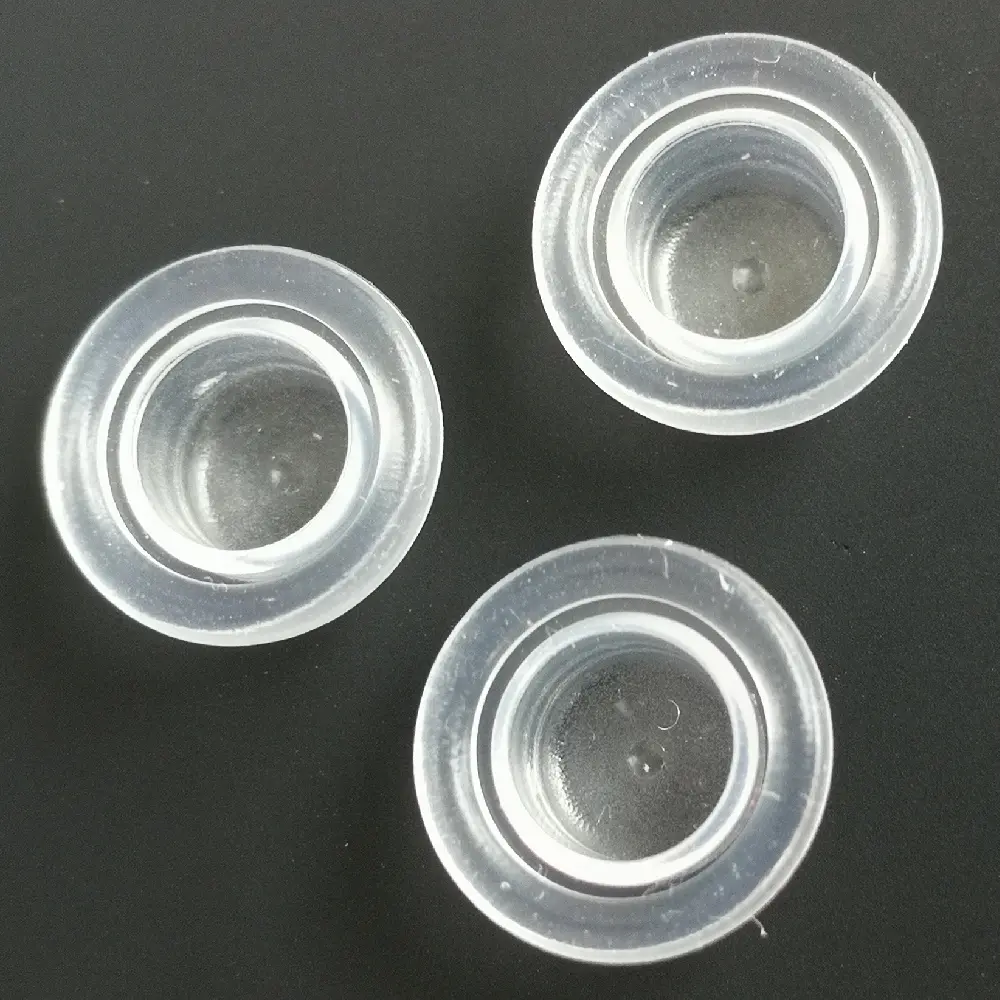

Liquid Silicone Rubber Prototyping for Press Button of Medica Devices

Low Volume Production with Manufacturing Process for Aluminum Housing and Lid

Manufacturing Services: CNC Machining, Tapping

Finishing Services: Anodizing

Material Used: Aluminum

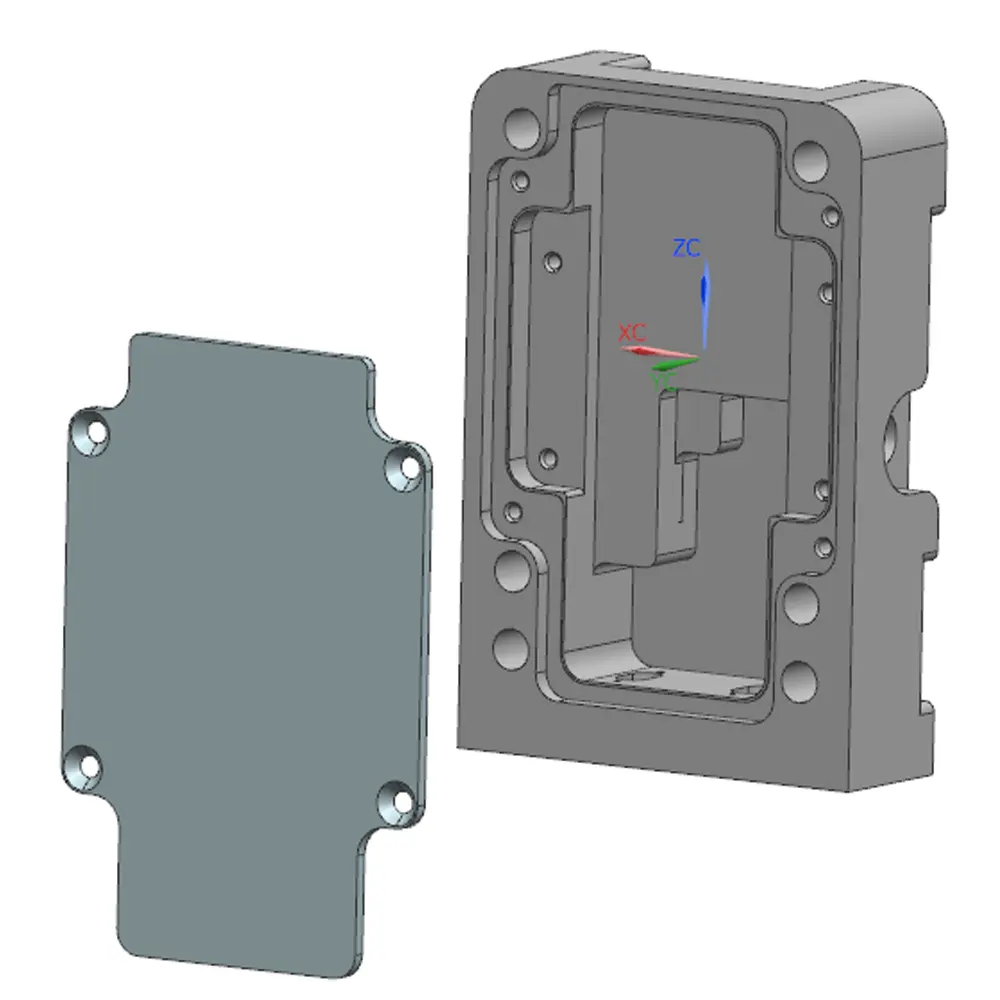

Prototype Type: Aluminum Housing Prototype

Challenge: Anodizing without oozing

Prototyping Quantity: 150 sets

Lead Time: 15 days

About the Housing & Lid Prototype

This project is a low-volume production project and the customer uses these parts for final products. All the parts would be assembled with internal parts and be shown to end users. The customer highlighted that the machining should be in high precision, the gap between lid and housing after screw them together should be consistent with tolerance of +/0.10mm. The offset in Z direction from housing to lid must be in +/-0.10mm. Additionally, the customer required to anodize these samples with an anodization color matrix. We plan to adopt CNC machining as manufacturing process for aluminum housing.

The key points of this project are the parts need to be anodized into different colors and the gap and offset must look the same in different color samples. OrideTech can provide manufacturing process for aluminum housing like CNC machining the housing and laser cutting the lid. This process design should be a low-cost way to make these samples. However, we adopted CNC as manufacturing process for aluminum housing due to high precision requirement.

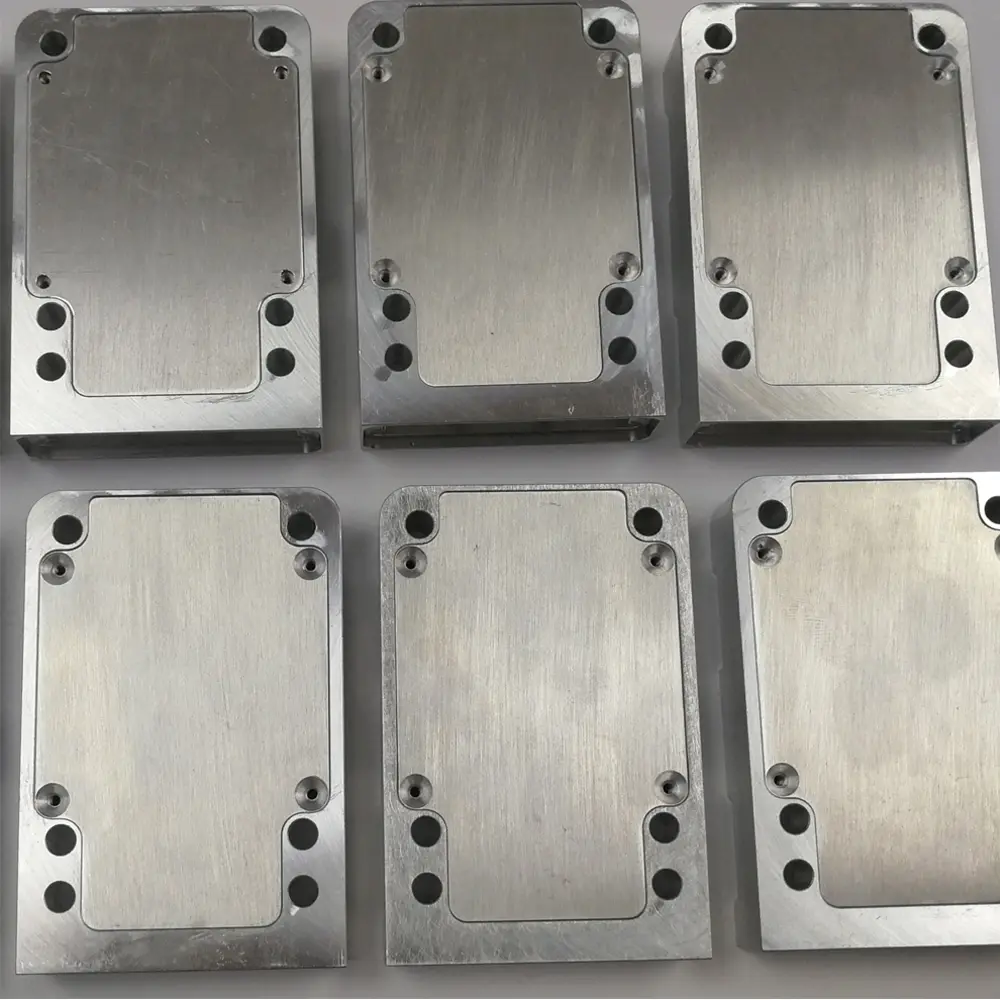

Challenges in manufacturing process for aluminum housing

This is low-volume production project with sample quantity of 150pcs. For this project, there are two challenges, one is how to keep consistent gap and offset between base housing and lid. Another challenge is how to anodize parts without oozing at tapped holes. To fix the first issue, we machined base housing and lid individually without drilling the matching holes. After these two parts machined out, we place them together and then drilled matching holes with assembled two parts together.

The second issue is a common issue happened in Anodization, especially the parts with two material connected together like iPhone housing. However, for the parts in this project, the issue is not difficult due to the same material of the parts. To fix it, we used a special silicone plug to fill in the holes during the anodizing. And after the anodization, we machined the chamfer and achieved the shiny chamfer with oozing at the end. And what we used became the best manufacturing process for aluminum housing. For more cases, you can review on our Facebook page or YouTube channel.