Design Tips to Sheet Metal

Design Tips to Vacuum Casting

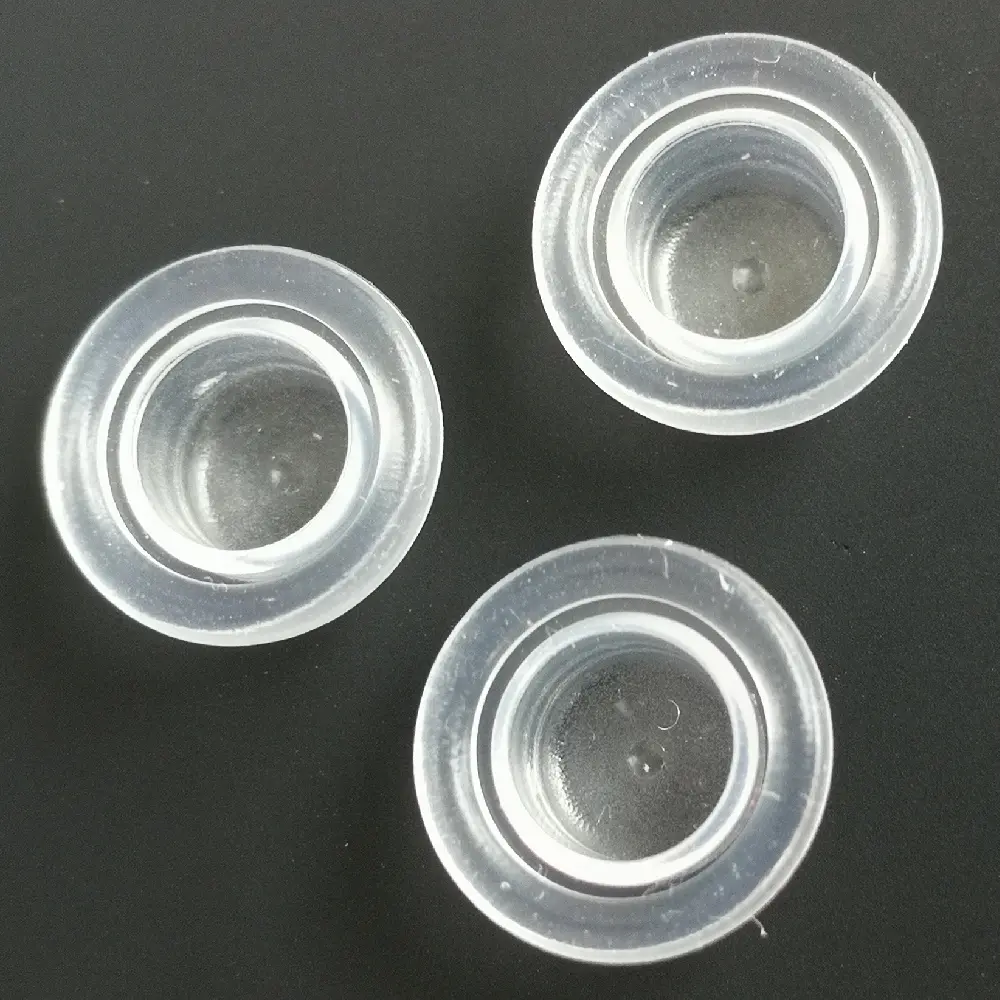

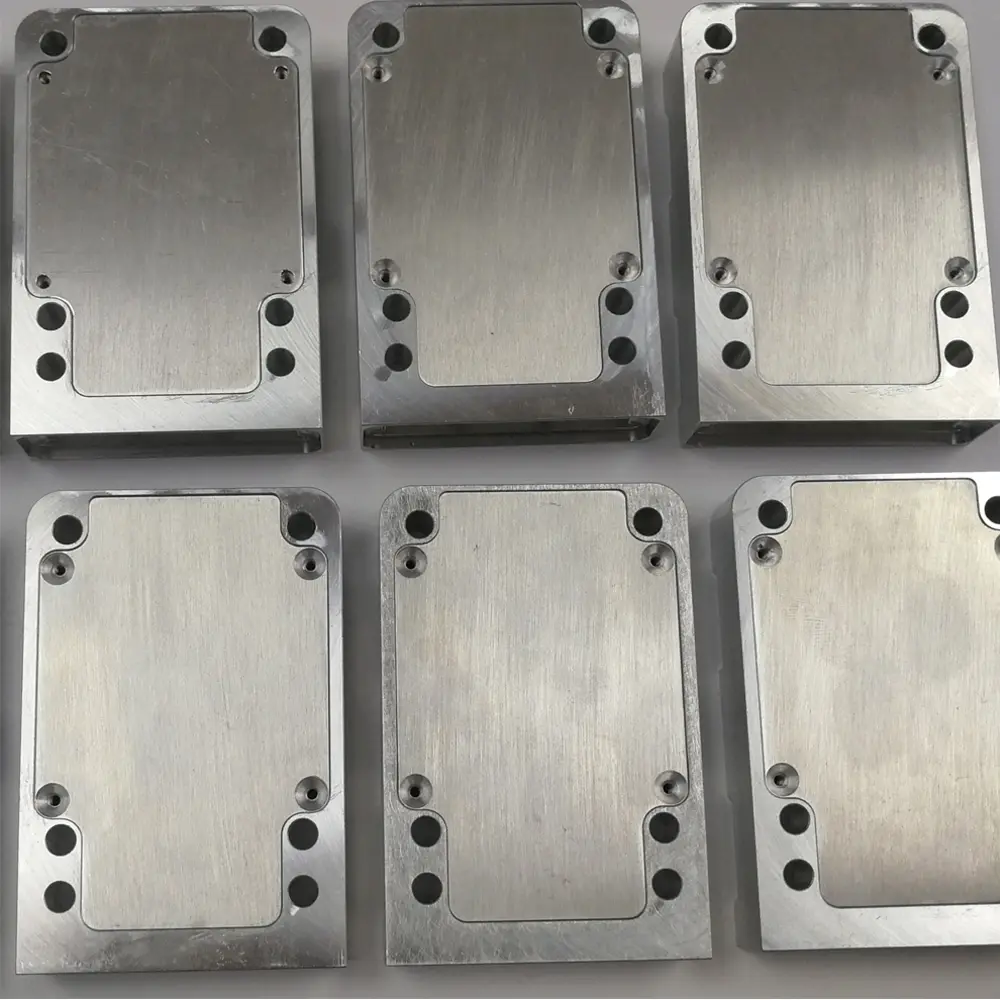

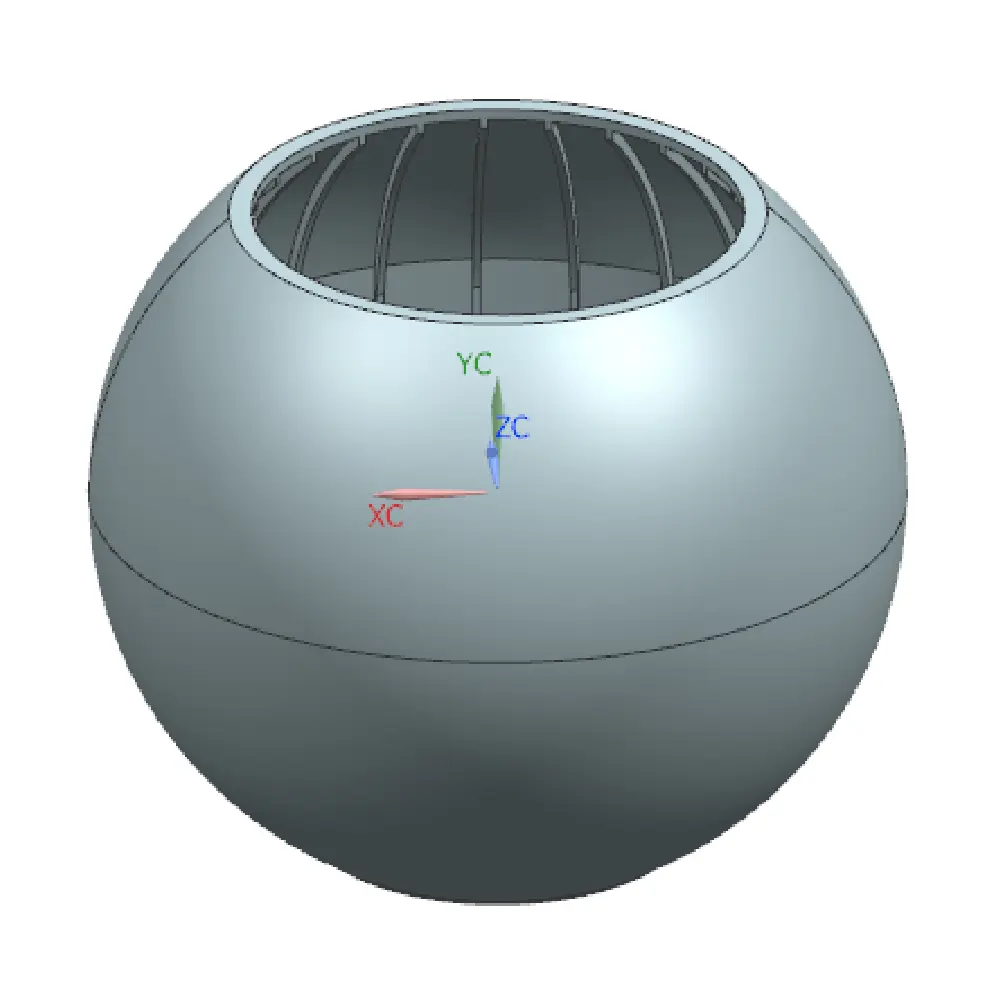

Low-volume Production for Housing with Vacuum Casting Process

Manufacturing Services: Vacuum Casting, Polishing

Finishing Services: Painting

Material Used: ABS

Prototype Type: Vacuum casting process prototype

Challenge: Reducing the assembly line in the middle

Prototyping Quantity: 100 sets

Lead Time: 15 days

About Vacuum Casting Process Prototype

This project is from our old customer who needs these samples for showing in an international exhibition. That means these vacuum casting process samples will be used to final products. The customer also dropped a hint that these samples are very critical since they planned to use them to attract more customers in exhibition. If these samples do help to getting more customers and orders, this project will go up to mass production soon. We need to help customer to find out all the issues during prototyping to prevent any issues happen in mass production. The customer will push the project from prototyping to mass production in only 2 months.

Challenges in Vacuum Casting Process Prototype

The geometry of this housing is not complex, the difficulties are how to make interlock runs smoothly and how to reduce the assembly line between top half and bottom half. For interlock, we helped customer to design a special interlock with inconsistence gap during sliding in and sliding out. This design makes very good feeling when you slide in the top cover to the bottom.

For samples using vacuum casting process, the dimension accuracy is not as samples from CNC machining. So, the assembly line will be a big issue. For reducing assembly line, the customer required that it cannot be seen after painting. We adopted polishing process and have our experience operators to polish it to class A surface. And then we do paint with different colors according to customer’s requirements. Fortunately, we got it done and made out the good surface and invisible line. However, the manual polishing process can be used for prototype samples and low-volume manufacturing samples. For mass production, it doesn’t work due to its high cost. How will we solve this issue during mass production for customers? The answer will be posted soon. For more cases, you can review on our Facebook page or YouTube channel.