A bus Model Prototype for Wind Tunnel Test in Laboratory with High Stability and Precision

Low Volume Production for a Multi-Camera Aluminum Housing with CNC Machining Techniques

Anodized Aluminum Enclosure with Specified Region Keeping Free from Anodization

Manufacturing Services: CNC Machining

Finishing Services: Anodization

Material Used: Aluminum

Prototype Type: Anodized aluminum enclosure

Challenge: Anodizing specified regions

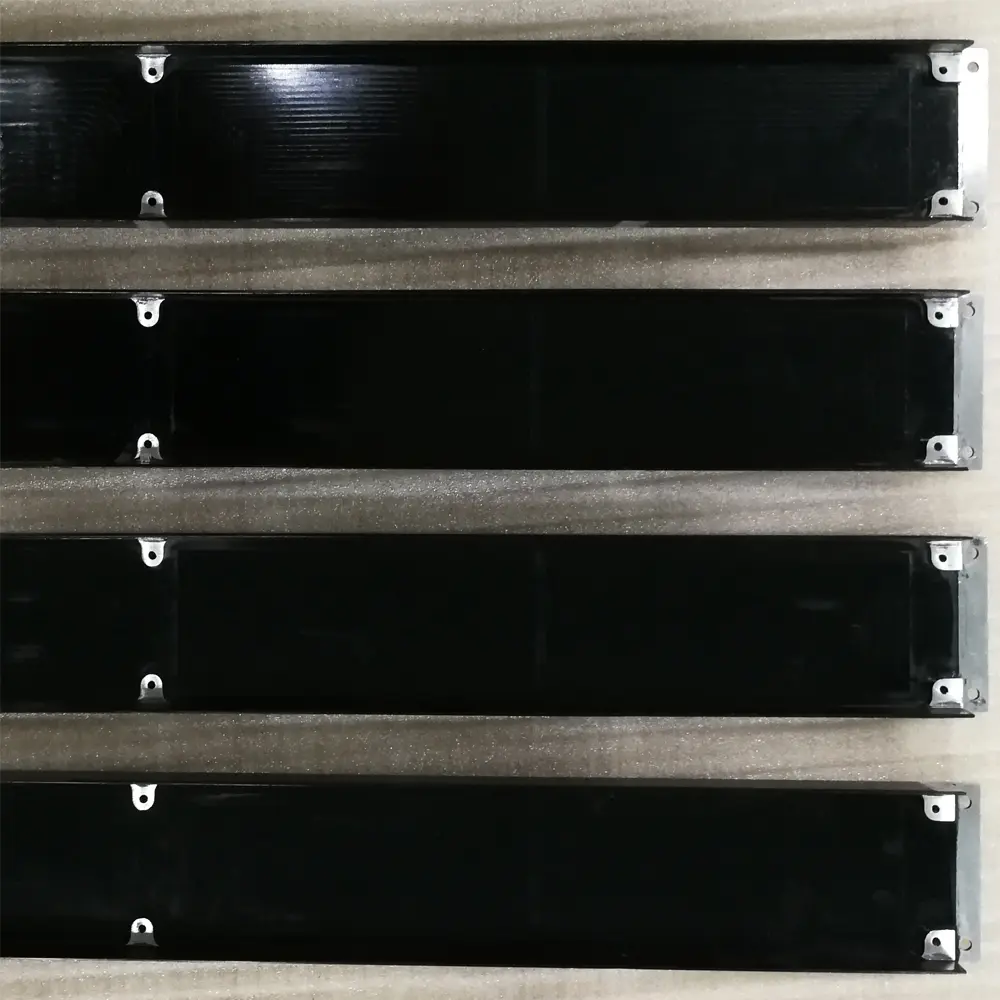

Prototyping Quantity: 32 sets

Lead Time: 12 days

About the Anodized Aluminum Enclosure Prototype

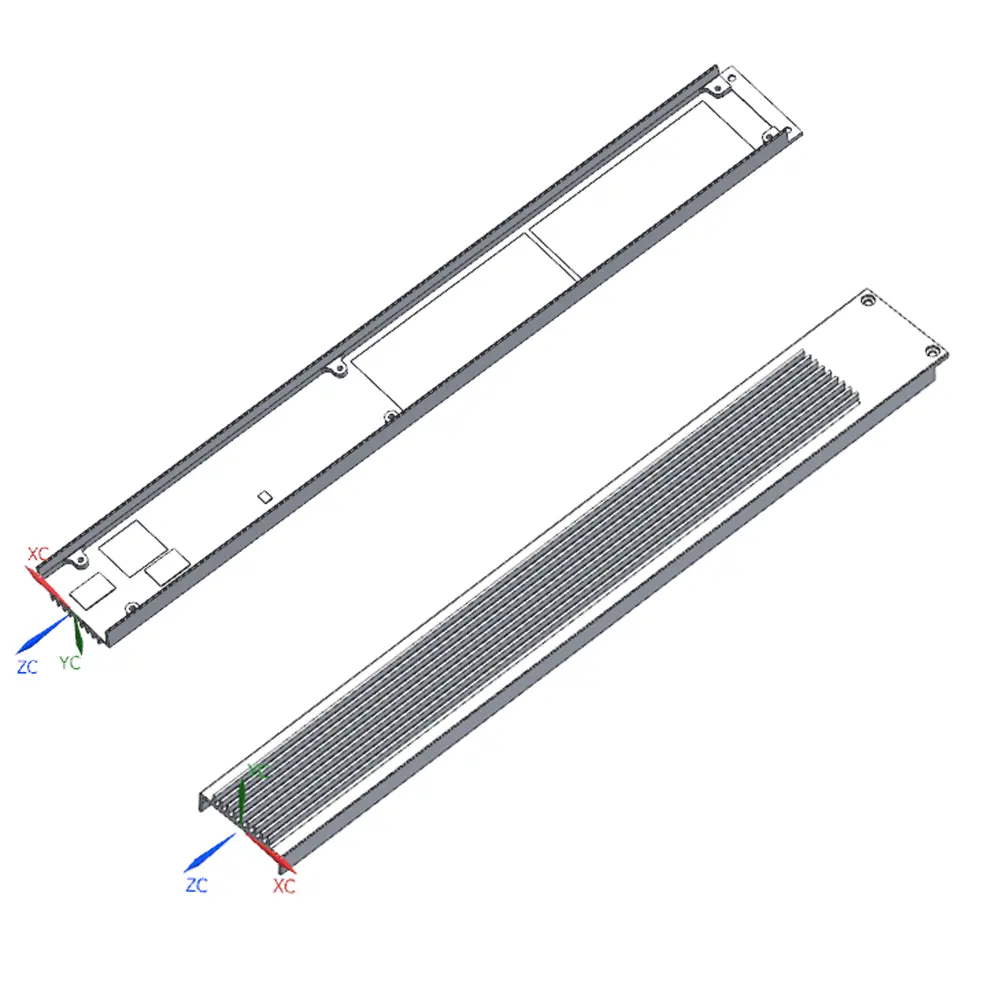

The anodized aluminum enclosure of this project is from a startup and the customer needs these enclosures for his new device which will be shown an international exhibition. The accuracy and the finishing effects of these aluminum enclosure are both important. The final device will be used on the car. And the customer would start mass production after exhibition. This enclosure is 1 mm thick and has many screws onto it. Also, they need black anodization since it is the cosmetic parts in final device. However, the customer required some specified regions must be free of anodization.

This product is going to mass production in a short time. We are expected to make samples and also try to find the potential issues in every manufacturing processes for customers. After the prototyping, we also need to provide detail process flowchart to customers since they will start the mass production of this product soon. And the mass production must run smoothly after prototyping production.

Challenges in Anodized Aluminum Enclosure Prototype

For anodized aluminum enclosure, if you need to anodize the whole parts, that is easy. If the part needs some specified region be free of anodization, it is more difficult. Generally, we have two ways to achieve it. One is masking the specified regions before anodization and another is anodizing the whole parts and then cutting out the specified regions with tiny depth by CNC machining. For masking process, it is very difficult to make the edge between anodized region and non-anodized region clear. So, this will make a fuzzy edge. For post CNC machining, it is easy to make the final anodized aluminum enclosure in a step between anodized region and non-anodized region. Also, the scratch and dent will be another issue.

Finally, we adopted a special way which is to anodized the whole parts and then use grinding to remove the anodization file of the specified regions. This process helped us to remove the anodizing film of specified regions and also keep flush to anodized region and non-anodized region. You cannot feel any steps by touching it between two regions. For more cases, you can review on our Facebook page or YouTube channel.