How to deal with the ECN samples which cannot be used?

A bus Model Prototype for Wind Tunnel Test in Laboratory with High Stability and Precision

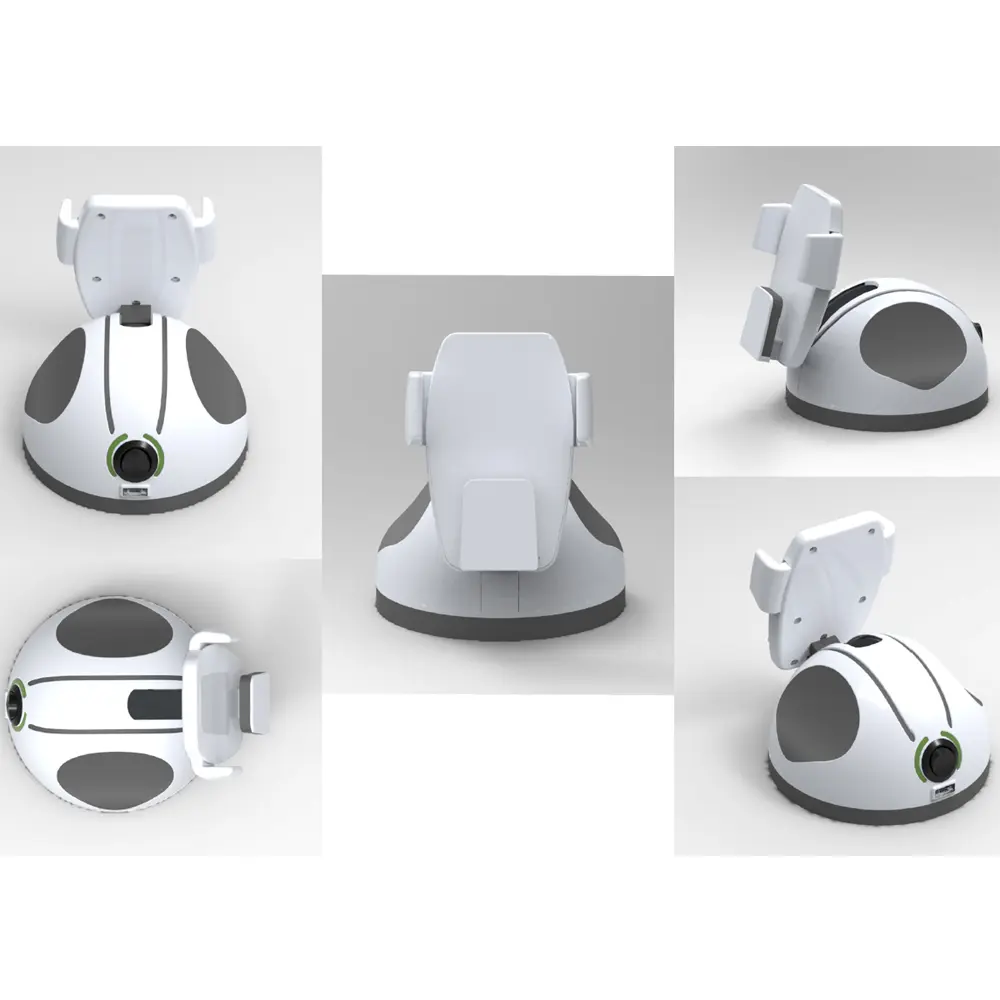

A 360 Degree Smartphone Video Chat Device Hardware Prototyping

Manufacturing Services: CNC Machining, 3D printing, Vacuum casting

Finishing Services: Polishing, Painting

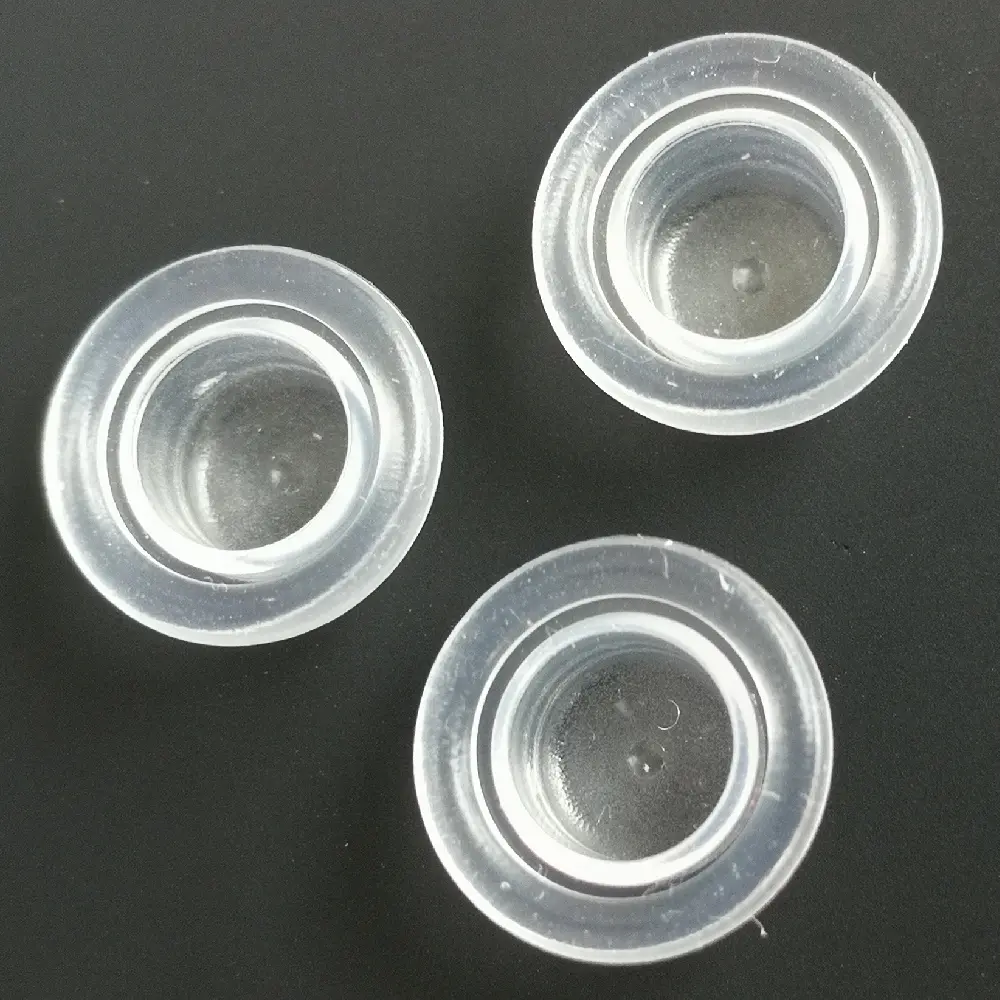

Material Used: Aluminum, Polycarbonate, Silicone, Acrylic

Prototype Type: Video device hardware prototyping

Prototyping Quantity: 6 sets

Lead Time: 10 days

About this hardware prototyping

The customer’s engineering team designed this video chat device. And they need these hardware prototyping samples in short time. The real samples of this hardware prototyping are very important to customers because they will show it to inventors. To some extent, this prototyping with all its samples will decide the future of this project. This product is a phone holder that allows you to interact with others during video calls. Go beyond a static view and follow the action as it happens. It is the only wireless device that uses technology to automatically connect your phone to it without any setup or Bluetooth pairing. Its smart sensor can recognize your hand gestures, and It rotates according to your hand movement. This video device product has a very wide application field, such as video call meeting between companies, video call chatting with friends and video monitoring for remote operation.

Challenges and Improvement Actions in This Hardware Prototyping

This this video device hardware prototyping includes many parts which are in different material, different geometry, different manufacturing processes and also different finishing. The final video device hardware prototyping samples needs to move freely. So, we need to machine all the parts in good tolerance and do pre-assembly before shipping. The great challenges are overcoming the tolerances stack from plenty of parts and finish this project in 10 days.

In order to overcome the tolerance stack, we manufactured every part in high precision and do manual polishing for making some part dimension in a little lower than nominal or some parts higher than nominal. After many times fitting and many times polishing, we finally make all the parts assembled in proper position and the video device hardware prototyping samples can move freely. Also, due to the project schedule, all the prototyping parts need to be finished in 10 days. In order to support this project, we input more machines to machine the parts individually at the same time and arranged night shift for full-time working to all manufacturing processes. For more cases, you can review on our Facebook page or YouTube channel.