How to Accelerate Product Development?

How to Make a Design Change Request During Prototyping Sample Fabricating?

How to Make Low Cost Prototypes for My Project?

Actually, all the customers want to make low cost prototypes for their development project. Only with low cost, the engineers can make much more designs to be real samples. At OrideTech, we have cost down meeting every month and we discussed and tried many ways to help customer to make cost down. We acheive cost down by simplifying design with DFM, stocking available raw materials, supporting pre-made parts, setting up more rapid equipment and providing 24 hours on line engineering negotiation. OrideTech aims to make low cost prototypes products for customers from many aspects. We’d like to list some ways and suggestions which can help to make great low-cost prototypes below:

1. Simplify the Design to Make Low Cost Prototypes

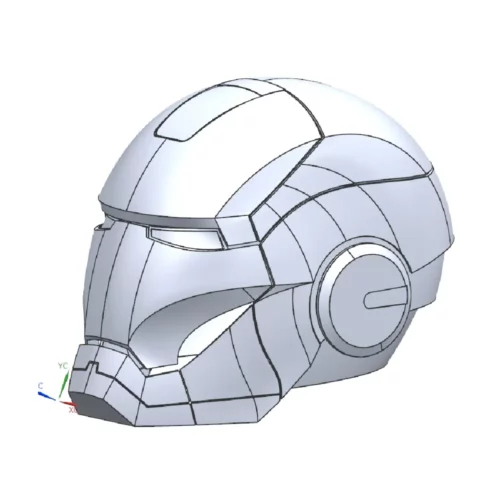

Simplifying the design can help reduce the number of components which is not needed or can be eliminated, which make low cost prototypes. OrideTech guys will feedback you DFM for simplifying your design with many proposals when we receive your 3D CAD models and 2D drawings. Also, we will propose you to change some features in your design which need costly machines or processes. To design, OrideTech propose to remove some deep interlock, sharp angles, thin wall, deep holes, narrow gaps and interfering features if possible. OrideTech will propose you how to avoid deep hole machining, wire EDM and sparkle EDM features.

2. Use Rapid Prototyping Technologies to Make Low Cost Prototypes

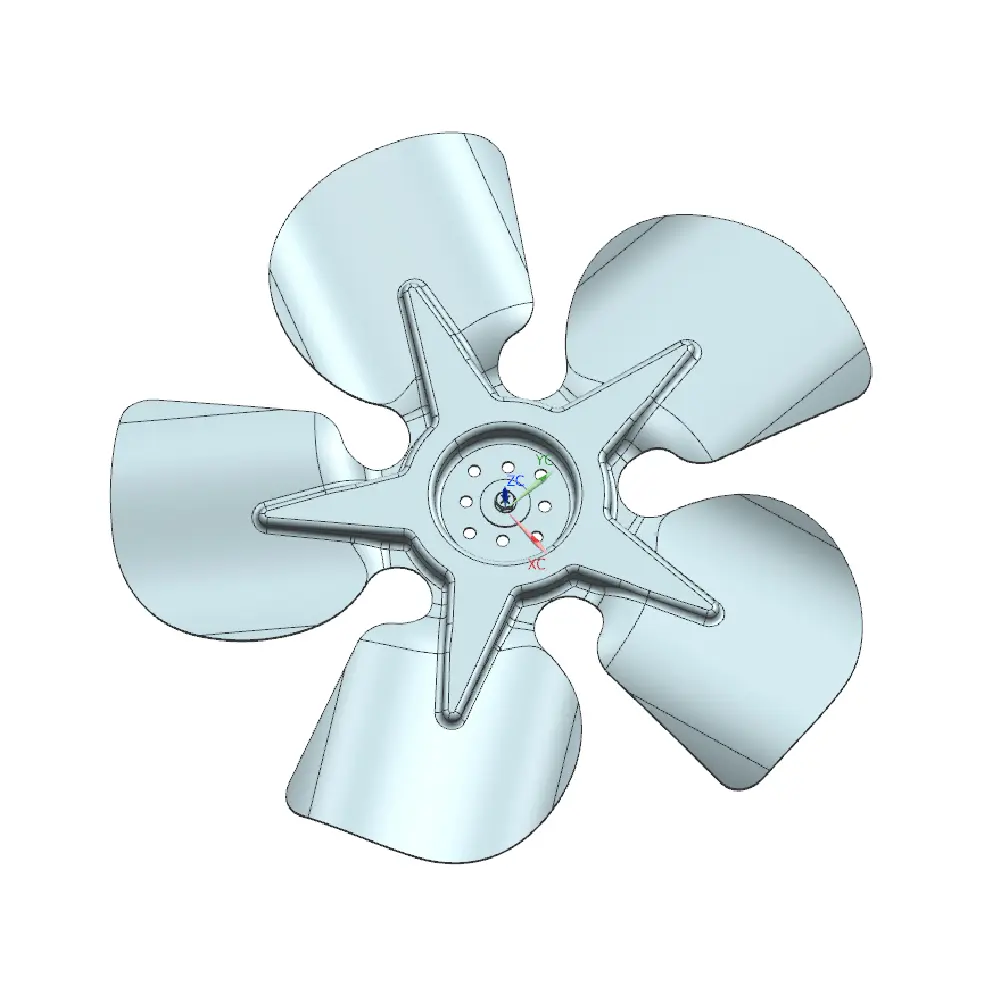

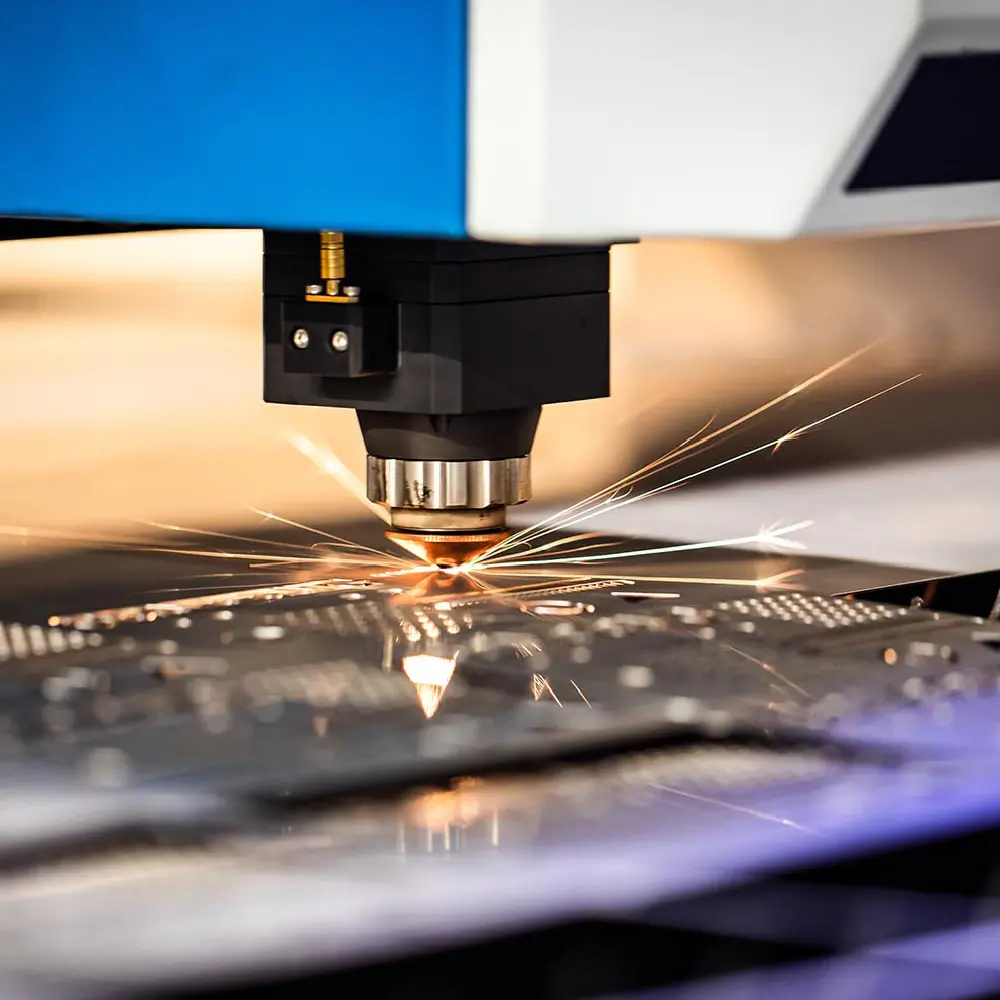

Rapid prototyping technologies such as CNC machining, Laser cutting and 3D printing can help you quickly create low cost prototypes than traditional manufacturing methods. OrideTech has both CNC machining, laser cutting and 3D printing processes. Your designs, material used and quantities define which manufacturing process will be chose. If your design is complex and the quantity is around 10pcs, CNC machining is the best choice. If you design a plate parts with simple holes and slots, we propose to use laser cutting. The cost of laser cutting is much lower than CNC machining. If your design is complex but don’t need high precision, 3D printing should be a good choice. Anyway, the engineers from OrideTech will always be here to provide you the suitable rapid prototyping technologies to fabricate your samples. And also, they will consider much things to help to make low cost prototypes for your project.

3. Work with Experienced Fabricators to Make Low Cost Prototypes

Working with experienced fabricators can help you identify areas where you can reduce costs without sacrificing quality. OrideTech guys are good at optimizing design and manufacturing process to save cost for you. If you would send your final parts assembly, using conditions, we will evaluate and provide you a way to make low cost prototypes for your project. Our manufacturing engineers and experienced fabricators are always enthusiastic to answer all your questions about the manufacturing process. And their skills and knowledge are open to you.

4. Use Off-The-Shelf Components to Make Low Cost Prototypes

Using off-the-shelf components instead of custom-made parts can save money and reduce lead times. In order to make low cost prototypes, OrideTech stocks many standard components and half processed parts. We stocked extruded profile, various shape metal and plastic material, skiving fins bar, etc. If your design is similar or same as OrideTech off-the shelf parts, we will provide you to use these parts to save cost. For some heat sink and housing products, we helped customers to save much cost by using our in-stock aluminum extrusion profiles. Most times, the customer needs to make some tiny changes to their designs. Also, for some customized products, we propose customers to machining them out from the similar parts we stocked. This can obviously save money and lead time for customers. Additional, for some plastic parts such ABS, PC, POM, PEEK, Garolite, We stocked many shape material, different thickness plates, different diameters bars and different ID&OD tubes. All these stocked materials are prepared for customer to make low cost prototypes with short lead time.

5. Consider alternative materials to Make Low Cost Prototypes

Using alternative materials, such as plastics instead of metals, can help reduce costs. For some projects, if the material is not necessarily specified, we will propose the material which can be used for your samples with low cost and fast purchasing lead time. And if your material is available in OrideTech stock, the cost will be reduced a lot. During prototyping, we propose not to use customized material due to its higher cost and MOQ (Minimum Order Quantity). For more blogs, you can review on our Facebook page or YouTube channel.