How to Make Low Cost Prototypes for My Project?

What Inspection and Measurement Service can OrideTech Provide?

How to Make a Design Change Request During Prototyping Sample Fabricating?

Making design change request during prototyping sample fabrication is a common occurrence. The design change always brings much cost waste to both customers and vendors. However, it is a must for customer to improve his project. In case of design change, both customers and vendors would consider many things such as when stop the machined samples? when input the new design into sample fabrication? how to deal with unfinished parts? And how to reduce cost waste? Oridetech provide you some suggestions below for your reference

1. Identify the Design Change Request

First, you need to identify what needs to be changed in the design. This can be done by reviewing the original design and identifying any areas that need improvement or modification. Oridetech also can help you to do this work and provide you proposals for making this changing in low cost from manufacturing side.

2. Use Off-The-Shelf Components

Once you have identified the design change, you need to evaluate the impact of the change on the prototype. This will help you determine if the change is feasible and if it will affect the functionality or appearance of the final product. And also, you need to confirm if this change affects the final assembly and your budget. If this design change request just impacts some features of the samples, OrideTech propose to make a simple matrix for your prototype samples, some in option #1 features and some in option #2 features. We can help to machine out both options samples. If the design change request occurs during prototype samples fabrication, please inform OrideTech as soon as you can, we can make manufacturing change according to you design change quickly. Oridetech has many manufacturing technologies to help to save cost of your design change request. If your design change request brings much cost increase, please inform OrideTech as early as you can, we can stop the manufacturing for your next step and OrideTech guys are willing to join your engineering meeting to provide some advices from manufacturing side.

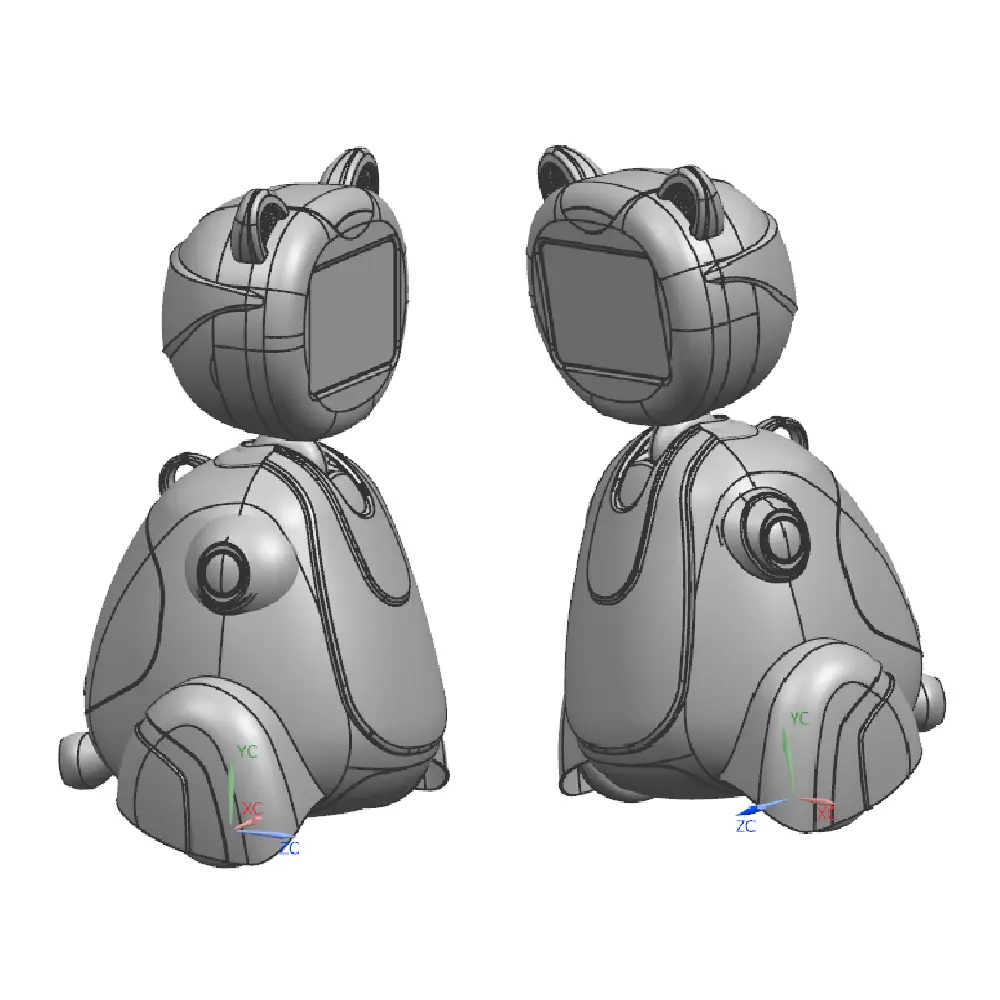

3. Create a New Design

If the design change request is feasible, you need to create a new design that incorporates the change. This can be done using computer-aided design (CAD) software or by sketching the new design by hand. And OrideTech will help you to evaluate the new parts from manufacturing side. Then OrideTech guys will remake the new design samples for you. Generally, in this case, OrideTech will provide you very fast sample fabrication service to reduce the delayed time for your project.

4. Test the Updated prototype

Once your design change requested confirmed and the updated prototype has been fabricated, it needs to be tested to ensure that the design change has been successful and that the updated prototype functions as intended. Some inspection and test can be done in OrideTech before shipping. This is very important to your project since we can remake the sample if it failed in the test. OrideTech will measure all the important dimensions according to your drawing, if you don’t provide 2D drawing, OrideTech will release internal drawing for your product to control the dimension. Also, OrideTech provide you many testing services such as pull force test, push force test, torque force test, section test, material test, assembly test and other out sourcing tests.

5. Updated the prototype

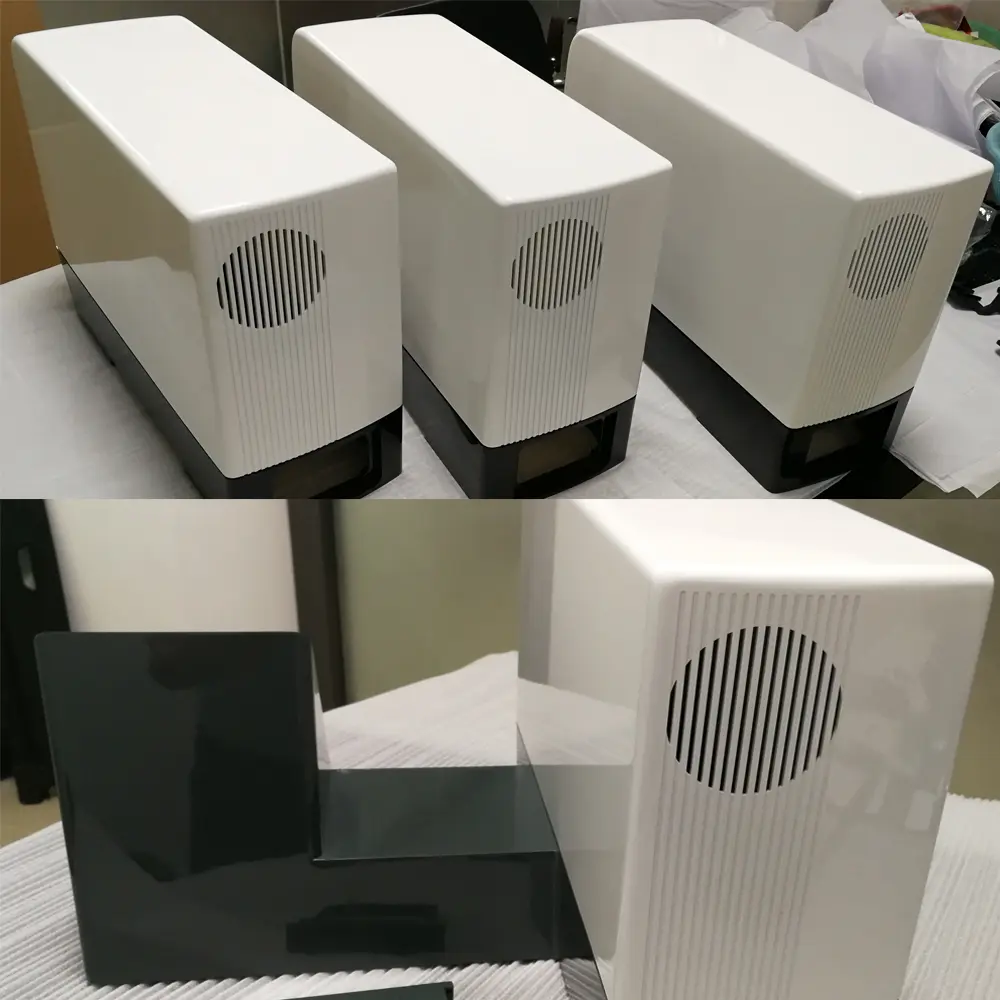

Once you have the new design, you need to update the prototype. This can be done by using rapid prototyping technologies such as 3D printing or CNC machining to create a new prototype with the updated design. OrideTech, besides CNC machining, 3D printing and Laser cutting, also has some other rapid prototyping technologies to help you to short the sample fabrication time.

By following these steps, you can make design changes during prototyping sample fabrication and ensure that the final product meets your requirements and specifications. It’s important to work with experienced fabricators such as OrideTech who can help you make design changes and create high-quality prototypes. For more blogs, you can review on our Facebook page or YouTube channel.