What is CNC Machining Manufacturing?

CNC (Computer Numerical Control) machining manufacturing uses pre-programmed computer software dictates the movement of tools and machinery to remove material from the workpiece. It involves the use of various cutting tools, including drills, end mills, lathes, and saws to cut raw materials into final parts. A computer program controls the movement of machining by monitoring the speed, angle, direction, chip load, feed and even coolant controls.

This level of automation allows for high precision and repeatability in machining. And the process is an integral part of modern manufacturing. OrideTech has different CNC equipment and accessories for cutting aluminum, copper, SUS, magnetism and various plastic materials for your prototyping models. And, we also provide CNC turning, Grinding, Spark EDM and Wire EDM for your rapid prototyping projects. For more details and videos, you can review on our Facebook page or YouTube channel.

Where is CNC Machining Manufacturing Used for?

This technique is widely used in modern manufacturing across many industries. It covers aerospace, automotive, medical, electronics and many other fields. With high precision, repeatability and automation capabilities, it has become an essential tool in the production of complex, high-quality, and customized products.

One of the primary applications of CNC machining manufacturing is prototyping and manufacturing of various components. It can machine automotive, transmission and hydraulic system components. Medical devices such as surgical instruments and prosthetics also use CNC machining to machine complex shapes in high accuracy dimensions. OrideTech uses CNC equipment for machining parts from rapid prototyping to low-volume production. Also, we can machine parts with high accuracy dimensions such as electronic enclosure parts and internal parts.

What Are the Advantages of CNC Machining Manufacturing?

Compared with traditional methods, CNC machining manufacturing offers several advantages:

- High precision and accuracy: The technique is capable of producing complex parts with high precision and accuracy for products.

- Efficiency: It can operate continuously, allowing for higher levels of productivity and faster production times for various of components.

- Reproducibility: It is designed to produce identical parts consistently and ensure accuracy and repeatability of these products.

- Flexibility: The process can be easily reprogrammed to manufacture various parts and make them more flexible and cost-effective.

- Cost-effectiveness: At OrideTech, the CNC machining is cost-effective due to its efficiency, cost savings and high consistency. And these machines can help customers to save cost of products development in rapid prototyping.

CNC Machining Materials

CNC machining can work with a wide range of materials, including metals, plastics and composites. In order to expedite the product development schedule, OrideTech stocked many commonly used materials. Also, these materials can help you to save both machining time and cost.

Plastic Material: ABS, Nylon, PEEK, PET, PMMA, Polycarbonate, PS, PVC, POM, Garolite

Metals Material: Aluminum, Copper, Brass, Stainless Steel, Magnesium alloy, Titanium alloy

CNC Turning Service

CNC turning is a manufacturing process that involves spinning a part while a single-point cutting tool removes material from the rotating workpiece. It can create cylindrical parts with exact dimensions and tolerances. OrideTech set CNC turning machines to produce high precision parts for various industries, including aerospace, automotive, medical, and electronics.

In CNC turning, the material being machined is mounted on a lathe, which rotates the workpiece at high speeds while a cutting tool removes material. The tool follows a programmed path, known as the toolpath, as it removes the material, creating the desired shape and dimension of the part. It is an efficient process that can produce cylindrical parts in high dimension accuracy for your rapid prototyping and low-volume production.

EDM Machining Service

OrideTech has both spark and wire EDM(Electrical Discharge Machining) for your product developing in rapid prototyping and low-volume production. Spark EDM is a machining process can shape hard and electrically conductive materials by removing material from a workpiece through repeated electrical discharges or sparks. We always use spark EDM for cleaning the sharp corner material and some features which CNC machining cannot reach.

Wire EDM is another type of EDM machining in which it uses a thin metal wire as the electrode to cut through a workpiece. We use it for cutting heatsink products which high and thin fins and also some features which CNC machining cannot be reached. All these EDM services are used in cast that the parts are in complex shape.

Grinding Service

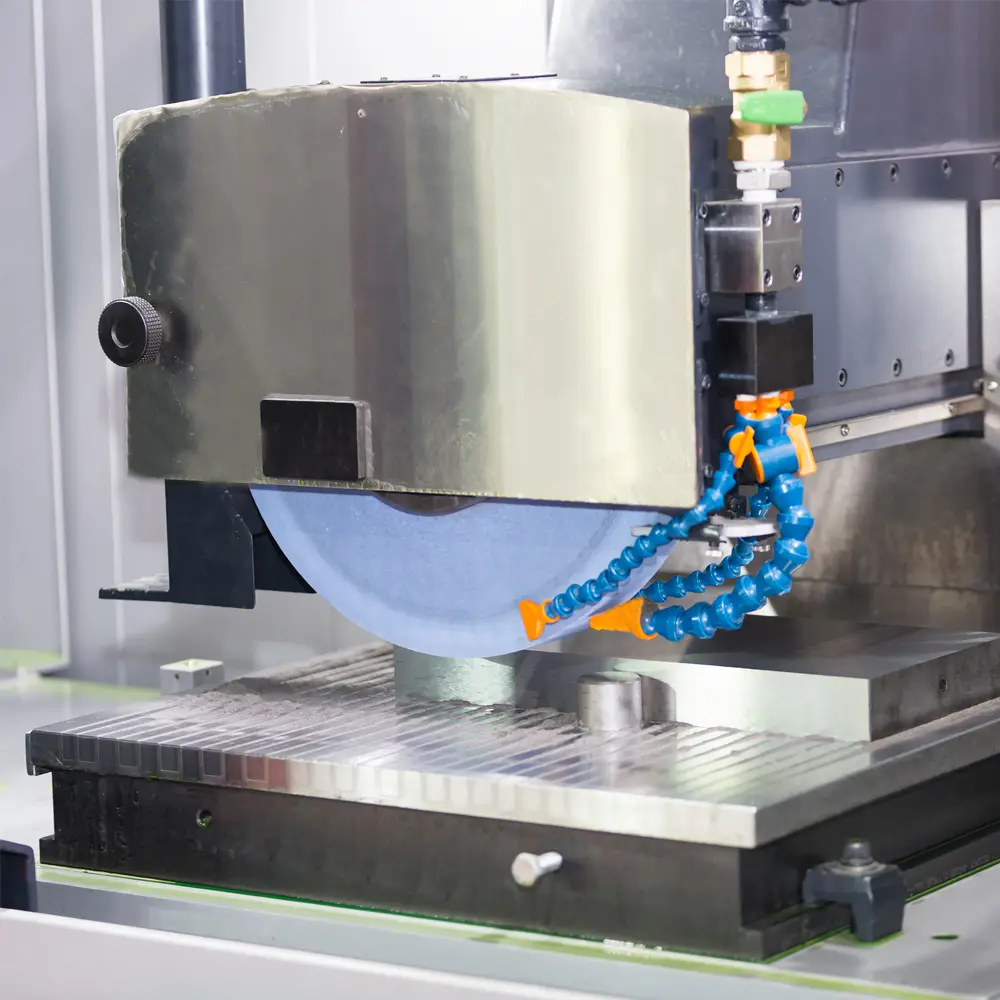

Grinding is a manufacturing process that uses an abrasive material to remove material from the surface of a workpiece. The abrasive material is typically a grinding wheel made of abrasive particles bonded together. The grinding wheel rotates at a high speed. And the workpiece is moving slowly against it to remove material. Grinding can also polish smooth surfaces, as well as sharpen tools.

We use grinding to achieve high precision and accuracy for some parts in rapid prototyping and low-volume production. Some metal parts from automotive, aerospace, and medical industries require very high dimension accuracy and high roughness surface. In this case, OrideTech uses grinding for some dimensions and super flat surfaces.