Low-volume Production for Housing with Vacuum Casting Process

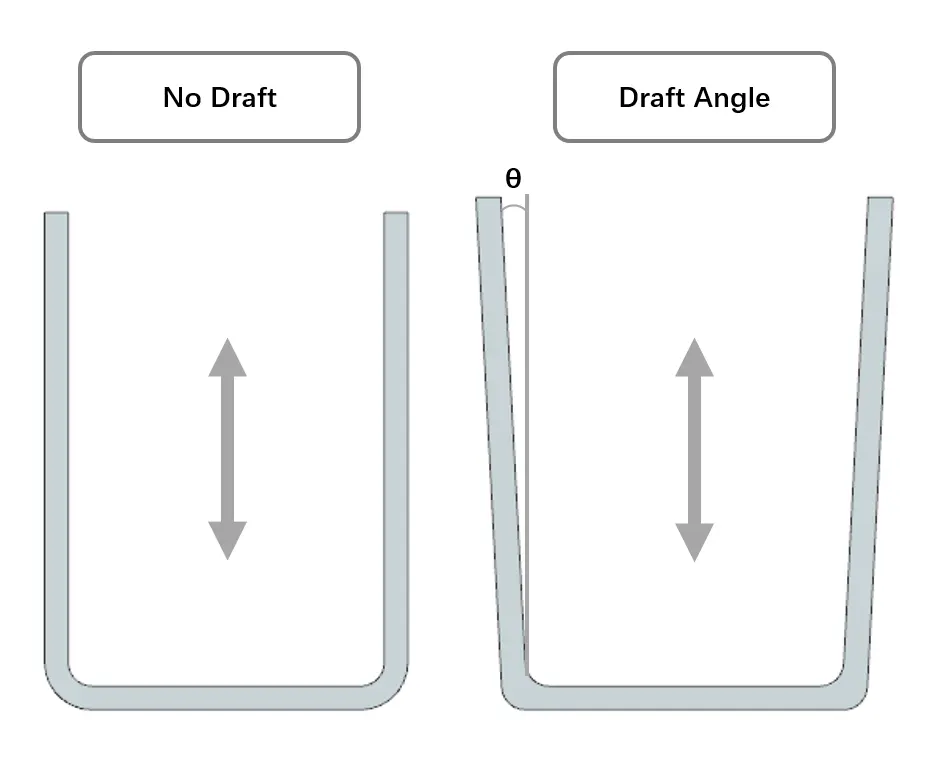

1. Draft Angles Design in Vacuum Casting Techniques

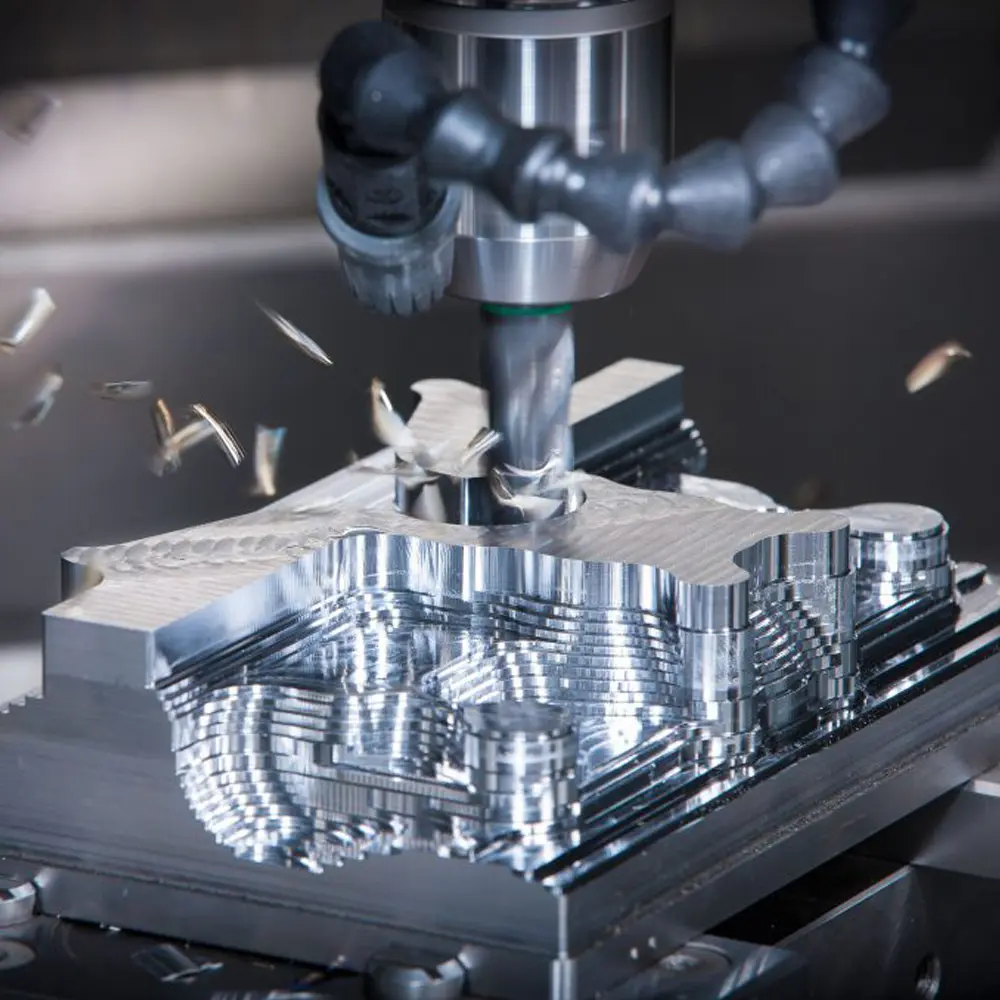

Draft angles are all about manufacturability. When designing for the vacuum forming process you must add draft angles to all sides to your parts. This can ease removal of the plastic parts from the tool once they’ve been formed. From OrideTech vacuum casting techniques, if you’re forming over a male mold, add draft angles of at least 3 degrees. But if you’re forming into a female mold, add draft angles of at least 5 degrees. For features like pocket, slot and blind holes, we propose to design same draft angles all sides. Sometime, you have to design a sharp angle, right corner or straight blind holes, the vacuum casting techniques cannot form the final geometry and we will use post process like CNC machining to cut out the final geometry. In this case, the cost and lead time will be both increased.

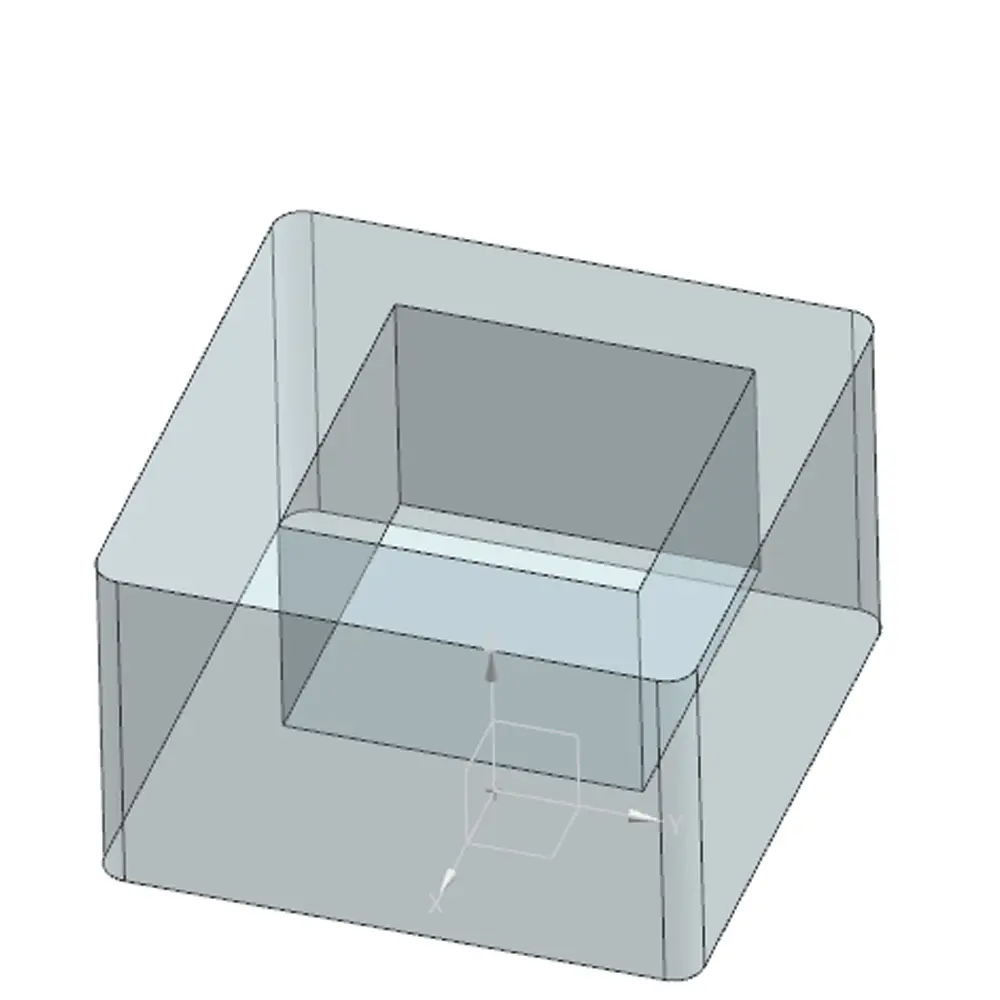

2. Pocket Depths Design in Vacuum Casting Techniques

For designing vacuum casting parts with pockets, please be sure that the pocket depth is no more than 75% of the smallest pocket width at the top of the pocket. If the pocket is too deep, the material will stretch too far over the vacuum casting tool and produce excessive thin and weak pockets. If you have to design deep pocket into your product, the vacuum casting techniques can not finish it. However, OrideTech will use some post-process like CNC machining to help you to achieve it.

3. Undercuts Design in Vacuum Casting Techniques

From vacuum casting techniques, we propose to avoid undercuts wherever possible, as parts with undercuts are difficult or impossible to remove from a standard vacuum forming tool. However, it is possible to vacuum form undercuts if your part has an undercut at one end, but an equal angle at the other, so that the direction of removal of the part from the mold tool has an equal or greater angle than the undercut. Another solution is using a split tool with side entrant tool that is removed first after forming, but this will increase the tooling costs.

4. Sharp Angles Design in Vacuum Casting Techniques

Due to vacuum casting techniques, vacuum casting doesn’t always work with parts that have sharp angles. The main reason is that plastic sheet may fold onto itself on sharp edges and reduce the mold quality. For example, if you adopt a star-shaped object as a core in the casting mold, the points of the star may cause webbing since they are too sharp. On the other hand, a pentagon-shaped core or a star shaped core with rounded corners would generate a high-quality mold with longer life span. OrideTech proposes to avoid the sharp angles when you design vacuum casting products. You can try to round all corners in your 3D models if possible. In vacuum casting techniques, it is common to round the edges of the models. Rounding edges can not only reduce the cost, but also helps with releasing the part from the mold. Even a 2mm radius can make a big difference, reducing webbing and improving the surface finish of the mold. In the case that the sharp angle is a must, OrideTech will have some post process to help to achieve it.

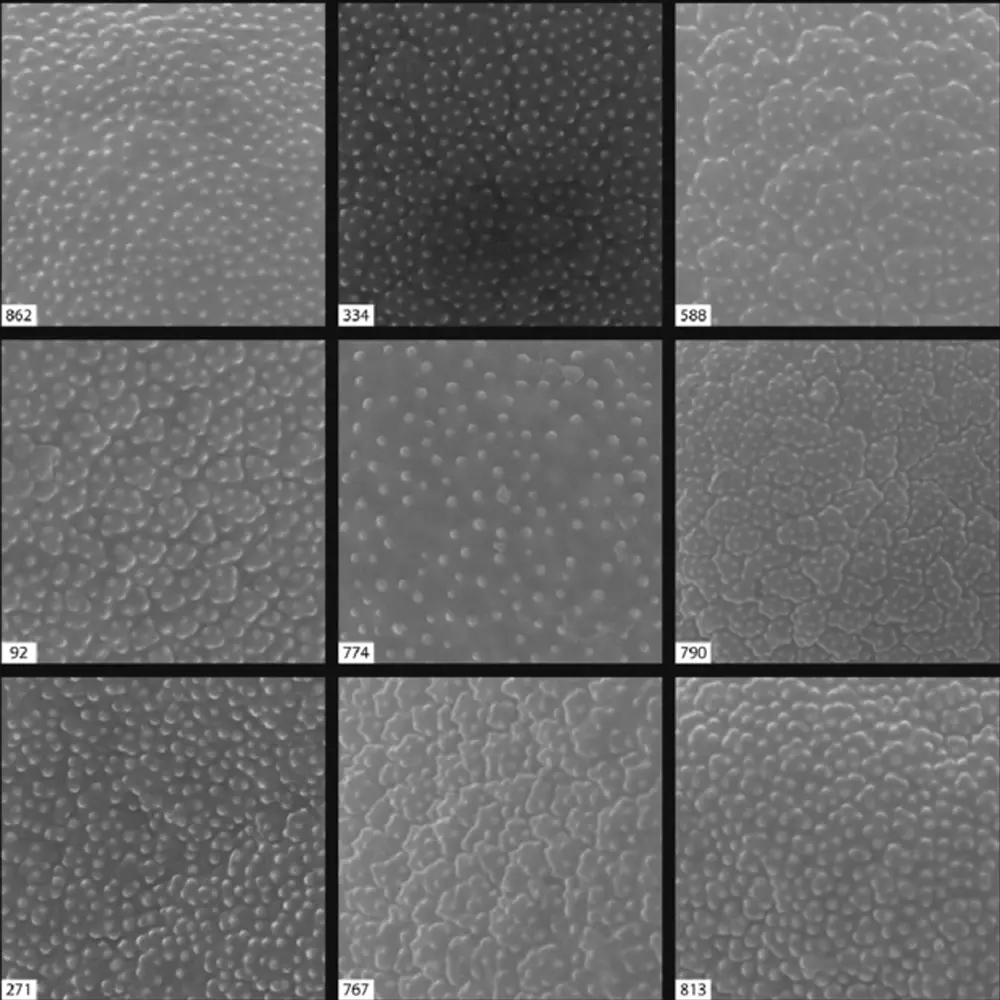

5. Remember to descript textures

For vacuum casting products, OrideTech has many ways to do finishing for it. So, please remember to describe textures on your drawings. From vacuum casting techniques, we always use a 3D printed objects as a core in the mold and this 3D printed object usually have a unique surface from printing and this texture will reflect on your vacuum casting parts. If you have need smooth surface on your mold and make perfect surface parts, please let us know. OrideTech will use post-process to 3D printed objects to match your surface requirements. Also, if you need to do painting, printing or laser marking, please remember to describe then on your drawing and OrideTech can finish all these finishing. If you want to do special color or gloss or texture onto your product, Oridetech, of course can do it. But this will increase the cost and lead time of your product. If you want to learn more vacuum casting techniques, please visit our Facebook page and YouTube Channel.